Creating custom bookcases from Michigan cherry and walnut is not just a woodworking project; it’s an exploration of artistry, precision, and the challenges that come with working with these beautiful hardwoods. As a craftsman with over 30 years of experience, I’ve learned that each project presents unique hurdles, and this recent endeavor was no exception. Join me as I share the process, the materials, and the challenges I faced while crafting these stunning bookcases.

The Vision

When a local family approached me to design custom bookcases for their home office, I was excited by the challenge. They envisioned a piece that would blend seamlessly with their existing decor while showcasing their love for reading. The plan was to use Michigan cherry and walnut—two woods renowned for their durability and beauty. Cherry, with its rich, warm hues, and walnut, with its deep, elegant tones, would create a striking contrast.

Before diving into the physical work, I spent time discussing the family’s needs and preferences. What size did they want? How many shelves would be ideal? Did they prefer a traditional style, or were they leaning toward something more modern? This initial phase of communication set the tone for the project and allowed me to visualize the final product.

Selecting the Materials

Michigan cherry is prized for its beautiful color, which can deepen and darken over time, while walnut offers a rich, dark palette with unique grain patterns. Both woods are readily available in our region, and working with local materials is always a priority for me. Not only does it support the local economy, but it also allows me to stay connected to the natural beauty of Michigan.

Once I sourced the cherry and walnut, I inspected each piece for flaws and imperfections. Selecting high-quality wood is essential for ensuring a beautiful finished product. After choosing the right boards, I began the milling process, which involved cutting and planing the wood to the precise dimensions required for the bookcases.

The Milling Process

Milling is one of the most crucial steps in any woodworking project, especially when working with hardwoods like cherry and walnut. Cherry is softer and easier to work with, but it can be prone to splintering. Walnut, on the other hand, is denser and requires careful handling to avoid tear-out during cutting.

I began with the cherry, carefully measuring and cutting the boards for the sides and shelves. I used a table saw and made sure to set the blade height just right to prevent splintering. Each cut had to be precise, as any error could result in wasted wood or mismatched panels. After cutting the cherry, I turned my attention to the walnut for the tops and accent pieces.

Facing Challenges: Humidity and Warping

As I progressed, I faced an unexpected challenge: the fluctuating humidity levels in West Michigan began to affect the wood. Cherry can warp if not handled properly, and I noticed some slight warping in my panels after a few days of sitting in the workshop. This was a wake-up call, reminding me that even the most seasoned woodworkers must respect the materials they work with.

To address the warping, I adjusted the workshop’s dehumidifier, ensuring that the environment remained stable. I also carefully re-sanded the affected areas, bringing them back to a flat surface. It was a time-consuming process, but I knew that a solid foundation was essential for the integrity of the final product.

Joinery: The Art of Assembly

With the panels milled and prepped, I moved on to the joinery. This is where craftsmanship truly shines. I opted for traditional mortise and tenon joints, which are not only strong but also visually appealing. Each joint had to be cut with precision, ensuring a tight fit that would stand the test of time.

As I worked on the joints, I marveled at how the rich tones of the cherry and walnut began to complement each other. The contrast was striking, and I could envision how beautiful the finished bookcases would be in the family’s home.

However, the joinery process was not without its challenges. I had to be extra cautious to ensure that the walnut accents aligned perfectly with the cherry panels. A small miscalculation could lead to gaps or misalignment, undermining the aesthetic appeal of the piece. Patience and attention to detail were my best allies during this stage.

Finishing Touches

After successfully assembling the bookcases, it was time for finishing. This stage is critical for enhancing the natural beauty of the wood while providing protection against wear and tear. I decided on a clear, satin finish that would allow the character of both cherry and walnut to shine through.

However, finishing these woods comes with its own set of challenges. Cherry is known for blotching when stained, so I applied a pre-stain conditioner to even out the absorption. For the walnut, I tested several finishes on scrap pieces to ensure a uniform look. After settling on the final finish, I carefully applied it with a brush, ensuring even coverage across all surfaces.

The Final Installation

After weeks of hard work, the moment of truth arrived: installation day. I loaded the bookcases onto my truck, each piece wrapped carefully to prevent damage during transport. As I drove to the family’s home, I felt a mixture of excitement and nervousness. Would they love the bookcases as much as I did?

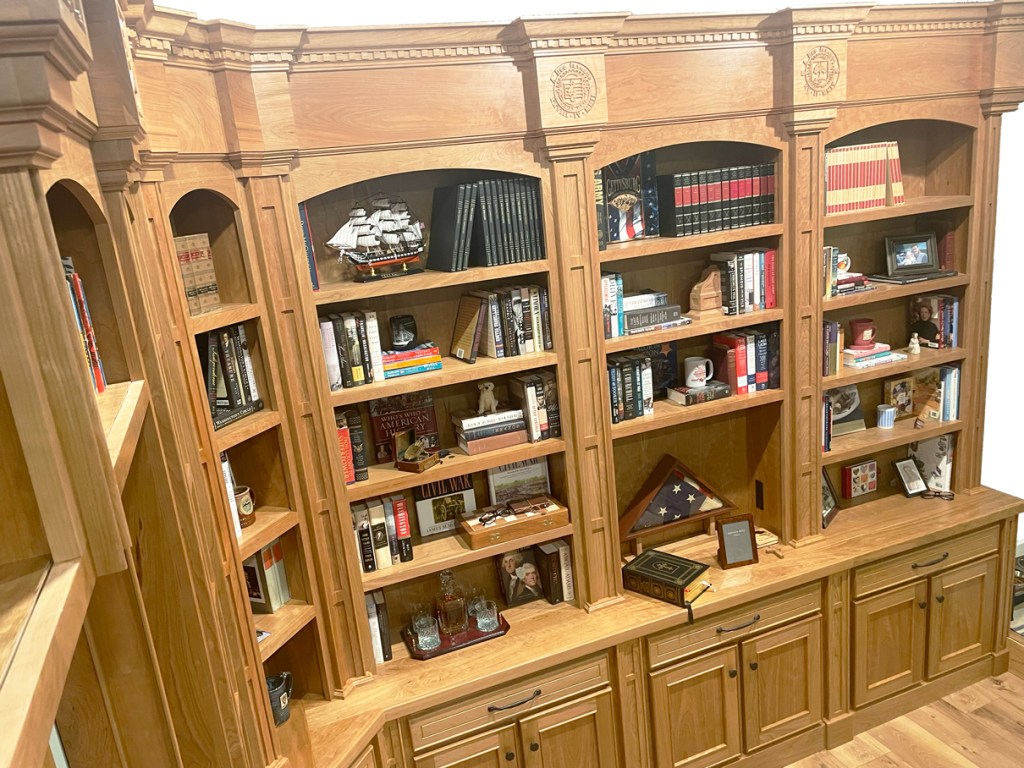

Upon arrival, I was greeted with smiles and eager anticipation. As I began assembling the bookcases in their designated spot, I could see the family’s eyes light up with every piece I installed. The cherry and walnut harmonized beautifully in their home, transforming the office into a warm and inviting space.

Reflections on the Craft

As I packed up my tools at the end of the day, I reflected on the journey. Each challenge I faced—whether it was managing humidity, addressing wood characteristics, or perfecting joinery—only added to the satisfaction of creating something unique and beautiful. The process of building custom bookcases from Michigan cherry and walnut was more than just a task; it was a reminder of why I love woodworking.

In every grain of the wood and every carefully crafted joint, there was a story. These bookcases would not only hold the family’s books but would also serve as a lasting reminder of their love for reading and the craftsmanship that went into creating them.

In the world of woodworking, challenges are inevitable, but it’s through overcoming them that we find our greatest achievements. Each project is a learning experience, and I look forward to the next opportunity to create something truly special. Whether it’s custom bookcases or another furniture piece, the art of woodworking continues to inspire and challenge me every day.

Leave a comment